CPTEK—Xing Duan's "1250 Ton Double Servo Motor Driven Forging and Punching Compound Press" rolled off the production line and successfully entered the top ten

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-11-07

- Views:0

(Summary description)After more than a month of solicitation and voting, vote counting and other links, the "Top Ten Events in the Stamping Industry in 2018" finally came out! CPTEK—Xing Duan's "1250 Ton Double Servo Motor Drive Forging and Punching Compound Press" was successfully finalized Top ten, and published in "Forging and Stamping" magazine.

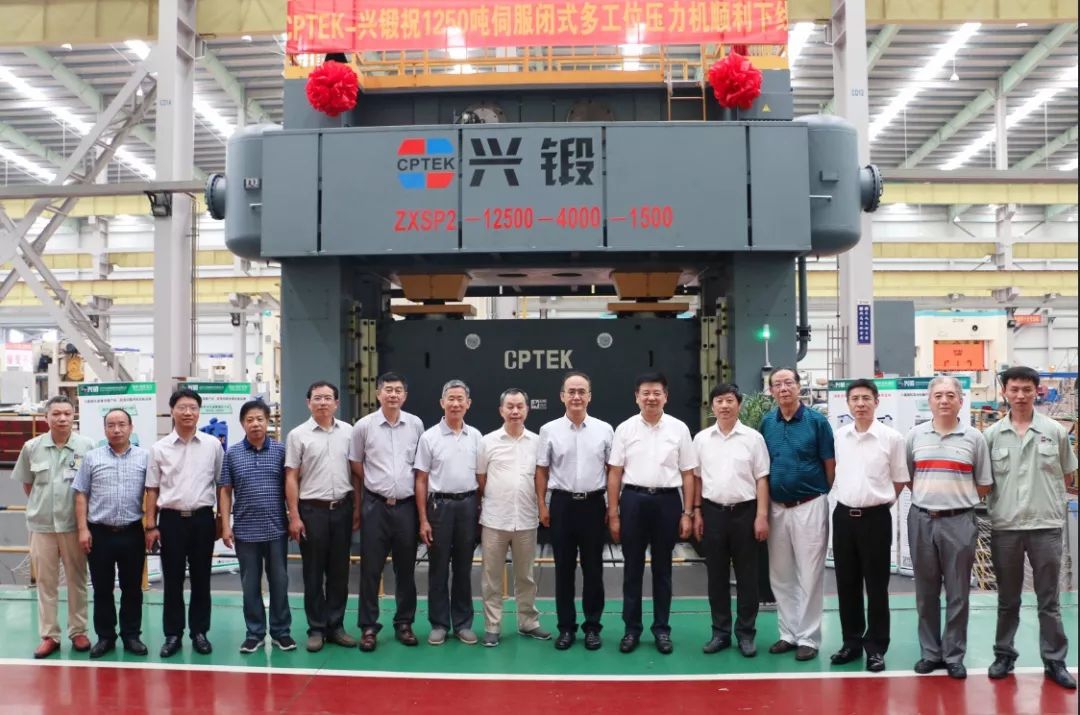

CPTEK—Xing Duan's "1250 Ton Double Servo Motor Driven Forging and Punching Compound Press" rolled off the production line and successfully entered the top ten

(Summary description)After more than a month of solicitation and voting, vote counting and other links, the "Top Ten Events in the Stamping Industry in 2018" finally came out! CPTEK—Xing Duan's "1250 Ton Double Servo Motor Drive Forging and Punching Compound Press" was successfully finalized Top ten, and published in "Forging and Stamping" magazine.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-11-07

- Views:0

After more than a month of solicitation and voting, vote counting and other links, the "Top Ten Events in the Stamping Industry in 2018" finally came out! CPTEK—Xing Duan's "1250 Ton Double Servo Motor Drive Forging and Punching Compound Press" was successfully finalized Top ten, and published in "Forging and Stamping" magazine.

On July 1, 2018, the “1250-ton double-servo-motor-driven forging and punching compound press” independently developed and manufactured by Jiangsu Zhongxing Xitian Numerical Control Technology Co., Ltd. (CPTEK—Xing Forging) was successfully rolled off the production line and won the provincial Bureau of Economy and Information Technology. Experts from the industry and universities agree that the overall technology of the product is in the lead in the country. The low-speed and high-torque air-cooled AC permanent magnet synchronous motor has been developed. The dual-motor synchronous drive mode has reached the international advanced level, and the production and testing equipment is complete. , Stable performance, reliable work, can meet the requirements of mass production, has the prospect of industrialization, and opened a new chapter of forging and punching compound forming.

The development goal of the project is the intelligent multi-station servo press production line and supporting solutions for the forging and pressing industry. The feature of the project is to break through the low-speed and high-torque servo motor of the multi-station servo press, control technology, high-precision manufacturing, large tonnage, etc. The key technology is to break the foreign monopoly and technological blockade, and realize the industrialization of the intelligent multi-station servo press production line, reaching the international advanced level.

This project is of great significance to China's forging industry, breaking through the foreign monopoly on the core technology of servo systems, and promoting the overall improvement of domestic enterprises' servo technology.

At the same time, the project was selected as the first set of products in Jiangsu Province, laying a solid foundation for the company to expand its market and establish its brand image. The company will continue to improve its technological innovation capabilities and core competitiveness, actively participate in international competition, break foreign monopoly technologies, fill domestic gaps, realize substitution of imports, and promote technological transformation and industry progress in the industry, and improve the overall technical level of my country's forging equipment. Make unremitting efforts to build smart high-end equipment!

The picture shows the photo of the first set of equipment at the customer's site, which has been highly praised by the customer and realized the customer's industrial upgrade!

Scan the QR code to read on your phone

Relevant information

-

Summer solstice

I wish you all a healthy Dragon Boat Festival! - Lifelong glory of unpaid blood donation 06-15

- The Dragon Boat Festival is a beautiful day with thousands of customs 06-12

- Small and full 05-21

Hotline:

400-881-5698

Address: No. 28 Shangshang Road, Zhongguancun Science and

Technology Park, Liyang City, Jiangsu Province

Phone: 0519-87962289

E-mail:service@cptek.com.cn

Jiangsu CPTEK Servo Technology Co.,Ltd. 苏ICP备20005947号

Powered by: www.300.cn changzhou IPV6