Observation meeting of 40000KN new hot die forging press automation line

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-10-17

- Views:0

(Summary description)Golden Autumn October CPTEK-Xing Forging Harvest Fruit

Observation meeting of 40000KN new hot die forging press automation line

(Summary description)Golden Autumn October CPTEK-Xing Forging Harvest Fruit

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-10-17

- Views:0

Golden Autumn October CPTEK-Xing Forging Harvest Fruit

Forging industry event

In the golden autumn and October, the harvest season is high and fresh, new and old customers of Xing Forging come from afar to participate in the observation meeting of the 40000KN new hot die forging press automation line hosted by Xing Forging. This observation meeting will show that it is independently designed and developed by our company. Manufacture the intelligent automatic production line of 40000KN new hot die forging press. This production line has been installed and passed the national inspection. The equipment has six product characteristics and adopts five new application technologies. It is the first set of new wide-table 40000KN hot molds in China The forging press has aroused a enthusiastic response in the domestic hot die forging industry, reflecting our company's continuous technological innovation, leading the development of industry trends, and promoting the craftsmanship and corporate responsibility of the intelligent forging industry.

On-site observation meeting

At 1:30 in the afternoon, the guests and friends present openly visited the company's exhibition hall. Ms. Hu Yujuan, the marketing manager, introduced the development history of Xing Forging, various equipment products, and the company's honors and customers' recognition and recognition.

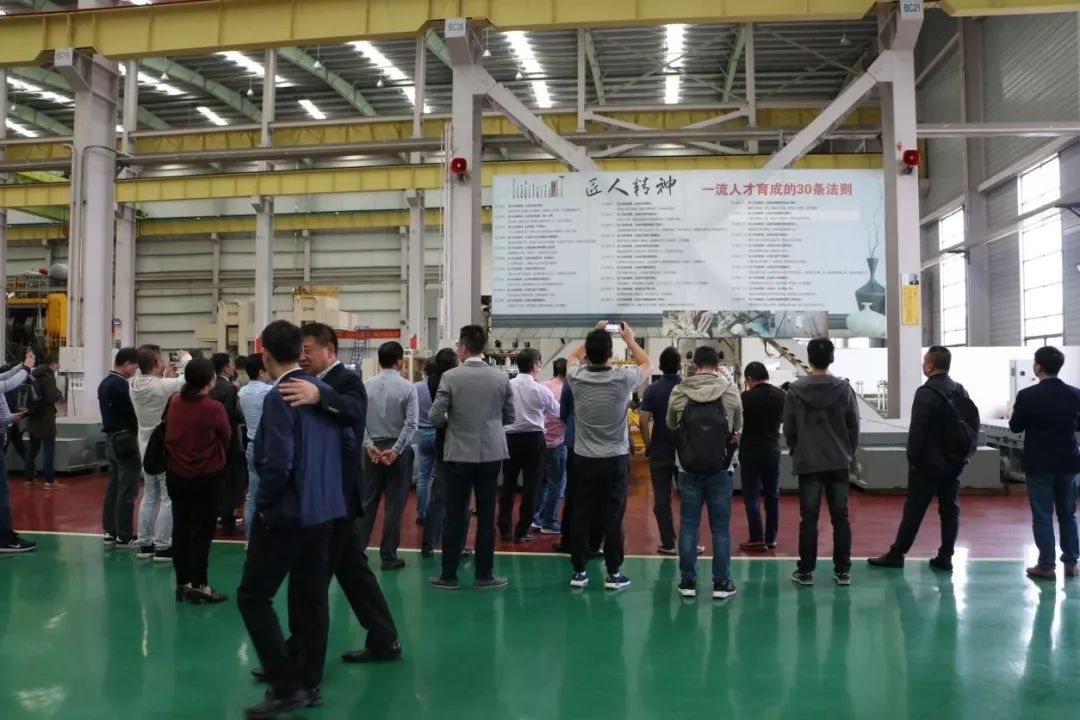

Later, under the leadership of the Xing Duan staff, they visited the factory together and introduced the company's major events over the years, production and processing equipment, and the "craftsman spirit" inherited by the company.

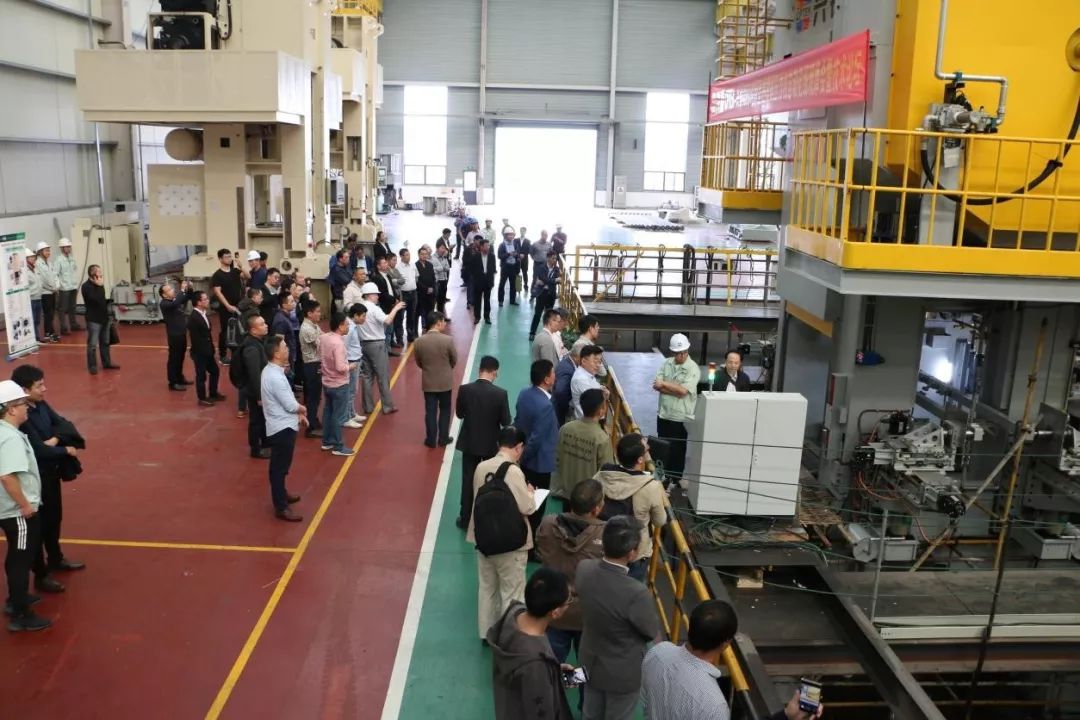

At the observation site of the automatic production line of the 40,000KN hot die press, Liang Zhiqun, deputy director of the Forging Technology Department of Xing Forging Company, explained the manufacturing process and product characteristics of the production line.

Deputy Director Liang explained in detail how we overcome difficulties in equipment manufacturing from the perspective of meeting customers’ high-standard actual requirements and modern production process requirements, and highly summarized the six major equipment features of Xingduan 4000T new hot die forging press automation line :

1. Large stroke;

2. Super wide table;

3. Hydraulic servo peak height adjustment and anti-boring car;

4. Mechanical ejection with large stroke and ejecting force;

5. New type of clutch brake;

6. Ten-axis automatic handling.

Customer experts in the forging industry present heated discussions about the equipment, and put forward many questions about the actual application of the equipment and product manufacturing. Deputy Director Liang answered in detail and discussed with everyone. The customer experts have a strong sympathy for the production line. Recognized.

Technical Seminar

After the on-site observation ceremony, moved to the meeting room to give a lecture on the latest application technology of the new 40000KN hot die forging press. The opening ceremony of the meeting was given by Mr. Zhang Qinglin, general manager of CPTEK-Xing Forging.

General Manager Zhang Qinglin, on behalf of the whole family of Xing Duan, expressed his warm welcome and heartfelt thanks to friends and relatives who came from afar!

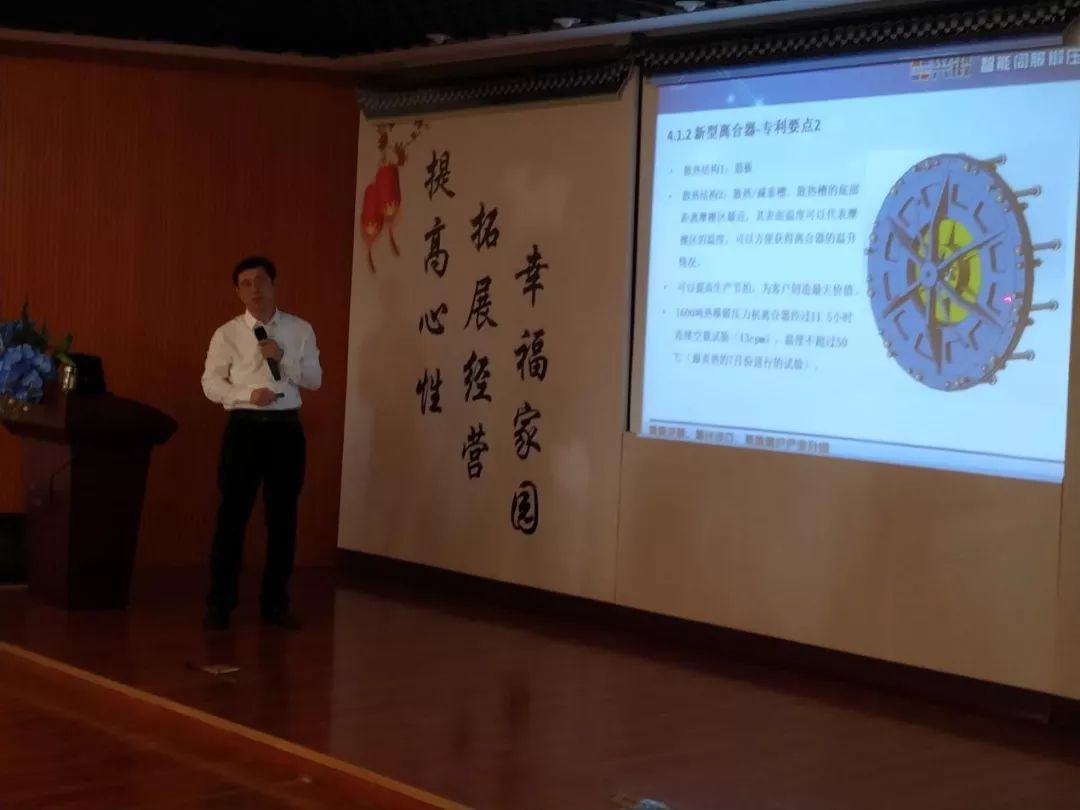

Subsequently, the director of the company's forging technology department Li Jiangguo explained in detail the design concept of the 4000T hot die forging press and five new application technologies.

Director Li first put forward the current status of the use of domestic presses, such as high failure rate, low economy, and high maintenance costs. The specifics are reflected in several points:

1. The clutch failure rate is very high, the friction block life is low, and there are very dangerous combo actions;

2. The brake angle and top dead center fluctuate too much, which makes it difficult to adapt to the needs of automated forging;

3. High seal height adjustment failure rate;

4. There is no dissolution of the car stew mechanism

5. The press has large vibration/shake;

6. The cylinder of the lower ejection mechanism has high linear velocity and high failure rate;

7. The guide rail is easy to wear.

In order to solve these deficiencies currently facing, Xing Forging Company put forward the principle of major faults, major reforms, minor faults minor reforms, with EUMUCO technology as the platform + major upgrades + integrated new technology design ideas, and the goal is to produce domestic leading new hot die forging pressure machine.

Xing Duan's new hot die forging press applies 5 new technologies:

1. New type clutch;

2. New brake;

3. New type of sealing height adjustment mechanism;

4. New type lower ejector mechanism;

5. New eccentric shaft and its dynamic load balancing technology.

Xing Duan independently develops and manufactures new hot die forging presses using five new technologies to completely improve the equipment defects in the current market and at the same time subvert the industry's inherent concept of domestic hot die forging presses.

In the free discussion session, on-site communication was very active, customer experts raised many questions and opinions, and the exchanges between peers were very happy, and the harvest was full. How to improve efficiency, how to improve the process, how to apply equipment, how to improve domestic intelligent forging equipment, etc. , Especially the design and application of Xingduan's new 40000KN hot die forging press, as well as the development trend of industry technology. This observation and exchange meeting was very successful. Xingduan built this exchange platform for business friends in the industry to learn from each other. progress.

Finally, Mr. Liang Boke, Executive Vice President of Xing Duan, made a summary of the meeting, thanking everyone for coming and the recognition and support of the industry.

Xing forging people, will fulfill the mission, forge ahead, and forge ahead.

Tailor-made, replace imports, revitalize China's forging industry, and create high-end intelligent manufacturing equipment!

All the guest leaders who came to CPTEK-Xingduan took a group photo in front of Mr. He Guangyuan’s inscription

Scan the QR code to read on your phone

Relevant information

-

Summer solstice

I wish you all a healthy Dragon Boat Festival! - Lifelong glory of unpaid blood donation 06-15

- The Dragon Boat Festival is a beautiful day with thousands of customs 06-12

- Small and full 05-21

Hotline:

400-881-5698

Address: No. 28 Shangshang Road, Zhongguancun Science and

Technology Park, Liyang City, Jiangsu Province

Phone: 0519-87962289

E-mail:service@cptek.com.cn

Jiangsu CPTEK Servo Technology Co.,Ltd. 苏ICP备20005947号

Powered by: www.300.cn changzhou IPV6